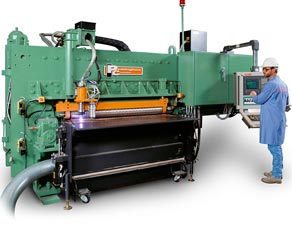

True 1 Pass Processing

The Peddinghaus plate machine comes standard with this unique machine design which saves you the hidden labor, inventory, and material handling costs

While other machine manufacturers taught they have a 1 pass design we can prove it. On the Peddinghaus Plate lines your cutting, measuring, part marking, part drilling, part punching are done in one continuous flow. |

![]()