|

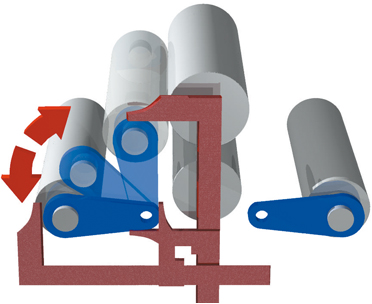

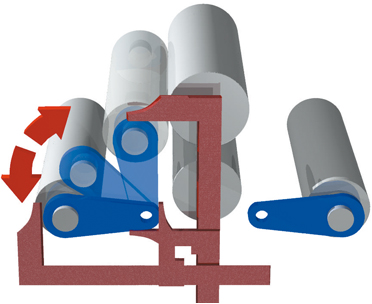

Two solid heavy swing arms guide each end of the side rolls pivoting firmly but smoothly with very high accuracy (same technology of the expensive accurate swing beam shears).

The first benefit of the Davi Planetary Swing Guides is to allow the absolute best prebending. The movement of the bending roll starts at a farer position but during its pivoting movement it swings toward the top roll. This wider movement converging through the top roll allows a favourable leverage that increases the power available at the prebending, reducing considerably the residual flat end. This leverage geometry input the maximum of the power exactly at the clamping spot, between the pinching rolls, allowing to get excellent results in extra short straight edge (improving the roundness of the shell) and the result of the accuracy.

|

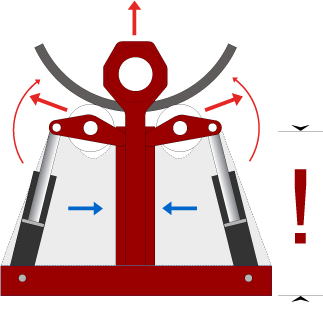

| The Davi Planetary Swing Guides reach and push against the top roll at a higher point, with the best geometrical angle, self compensating a part of their load and reducing the pushing effect under the top roll, affected by lesser deflection and they require a lower crown.

The Davi Planetary Swing Guides "wrap" the plate hydraulically pressed around the top roll on a longer section compared to the linear slipping guides, reducing substantially the re-opening due to the material spring back effect, allowing to get parts rolled to much tighter diameters (down to less than 1.1 times the top roll diameter, vs. 1.4 - 1.5 times common to the plate roll with linear sliding slipping guides).

The planetary swing guides completely eliminate the slipping sliding friction. They don't require anymore the frequent cleaning from mill scale to aoid the premature wear, common to the linear guides. They don't require anymore the maintenance and lubrication absolutely necessary on the linear guides.

The planetary swing guides extend the life of the machine, increasing its resale value. They also increase by 30 - 35% the capacities of the machine on tight diameters.

No limits to cone in tight diameters and to remove the closet shells horizontally, as the planetary swing guides allows to keep the frame lower than the rolls upper axis. |

|

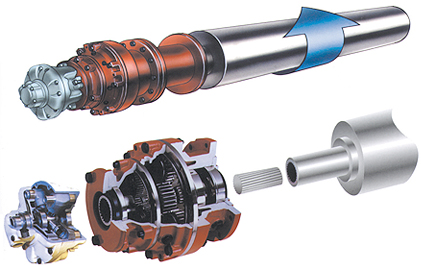

First and only plate roll, all around the world, employing since the end of the '80s high tech solution never requiring any service or lubrification for the whole machine life.

Each bearing is fully greased and sealed for its whole working life. They are lubrification-free and virtually wearing- proof.

Low-efficiency system (reduction units, bronze bushings, gear belts, carding, rectilinear guides) replaced by new high-efficiency solution: hydraulic planetary drive directly splined on roll shaft, friction-free swing guides, friction-free self aligning bearings, multi-way hydro power system.

They are the peak of the today available technology allowing hard reduction of load losses (passive power) keeping the real force available on plate to bend (active power). Energy Saving Technology comply with the International High Efficiency Standards. |

![]()