|

Introducing the world’s first die with Lean visual management technology. The Mate EasyView™ Slug Free® die combines a colored O-ring for clear and instant identification, Slug Free die geometry for improved piece part quality, and increased machine up time.

Use the simple removable O-ring to identify a specific feature of the die making it faster and easier for the user to make the correct decision every time. Eliminate wasted time looking for the correct tool.

Order Mate EasyView Slug Free Dies today.

Examples of Use |

Criteria |

Color |

Material Type |

Mild Steel |

Black |

|

Aluminum |

Red |

|

Stainless Steel |

Yellow |

|

|

|

Material Thickness |

0.040(1.00) |

Green |

|

0.059(1.50) |

Yellow |

|

0.078(2.00) |

White |

|

|

|

Die Clearance |

0.008(0.20) |

Red |

|

0.012(0.30) |

Yellow |

|

0.016(0.40) |

Green |

|

|

|

Machine Location |

Machine #1 |

Red |

|

Machine #2 |

White |

|

Machine #3 |

Black |

|

|

|

Shift |

Days |

White |

|

Nights |

Black |

|

|

|

Status |

OK to use |

Green |

|

To be Sharpened |

Red |

| Eliminate slug pulling

Reduce tool breakage

Improve tool life

Increase quality |

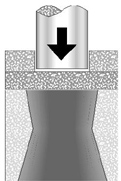

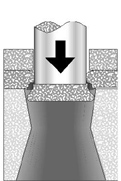

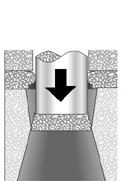

Mate Slug Free® dies eliminate slug pulling. Slug pulling is a condition where the slug returns to the top of the sheet during the stripping portion of the punching cycle. The slug comes between the punch and the top of the sheet on the next cycle. This causes damage to the piece part and the tooling. Slug Free dies eliminate this problem.

The Slug Free die has been designed with an opening that has a constriction point below the surface so the slug cannot return once it passes through this point. Once the slug is separated from the punch, it is free to fall away from the punching area. Slug pulling is eliminated.

Material held securely by stripper before punch makes contact. |

Punch penetrates the material. Slug fractures away from sheet. |

Pressure point constricts slug. Punch stroke bottoms out as slug squeezes past pressure point. |

Punch retracts and slug is free to fall down and away through exit taper of the Slug Free® die. |

|