|

The new Mate Ultraform® P&F Forming Tool System is a special assembly tooling system designed for use with the Punch-And-Form (P&F) option on Amada punch presses.

Mate Ultraform P&F forming tools are fully compatible with Amada machines that include the P&F option, and are configured with an eccentric turret and manual tool change (typically Amada Z-Series models).

Punch-and-Form (P&F) Concept

The P&F feature maximizes the feed gap of the machine, because the top surface of P&F lower forming tool assemblies remain at the same height as standard dies. The P&F feature maximizes the feed gap of the machine, because the top surface of P&F lower forming tool assemblies remain at the same height as standard dies.

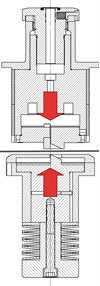

Machines configured with the P&F feature include an upforming mechanism below the lower turret. The upforming mechanism engages with the lower forming tool to raise the lower insert to create a form in the material, while leaving the stripper plate at the same height as a standard die.

The Mate Ultraform P&F Forming Tool System combines an Ultraform punch holder with fully interchangeable upper forming tool inserts, and a custom designed lower assembly.

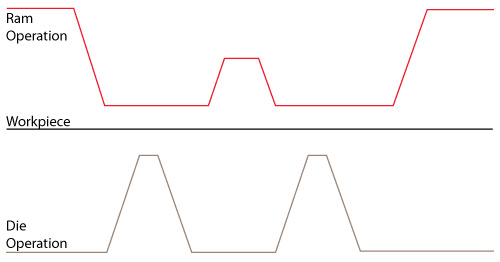

The Ultraform P&F lower forming tool assembly includes the “driver” that engages with the P&F upforming mechanism of the punch press. The diagram below, shows the sequence of ram operations which are controlled by the punch press.

Punch presses configured with eccentric turrets provide the unimpeded access to the top of the die holder which is not possible with conventional turrets. This allows installation of the much longer Ultraform P&F lower forming tool through the top of the die holder.

Ultraform Concept

One adjustable length holder can be used with a variety of special forming inserts. The benefits include reduced tooling cost, increased flexibility and the length of the assembly can be accurately pre-set.

Length Adjustment: the push-button length adjustment mechanism allows the overall length of the assembly to be set in 0.002(0.05) increments, without disassembly, of removal from the machine. The length adjustment is made below the collar of the assembly, thus maintaining the gap between the ram and the tool at top of stroke.

Angle Setting: All Ultraform inserts can be set at 0, 90, 180 and 270 degrees for maximum flexibility.

Extended Life: Ultraform holders provide internal channels and external grease grooves to allow lubrication of forming tools. The hardened guides, combined with the lubrication grooves, reduce friction and extended turret bore life.

Mate Ultraform P&F forming tools are available in 1-1/4” B, 2” C, and 3-1/2” D stations. Contact a Mate application specialist to discuss your next forming tool application.

|